Case Studies

Case Studies

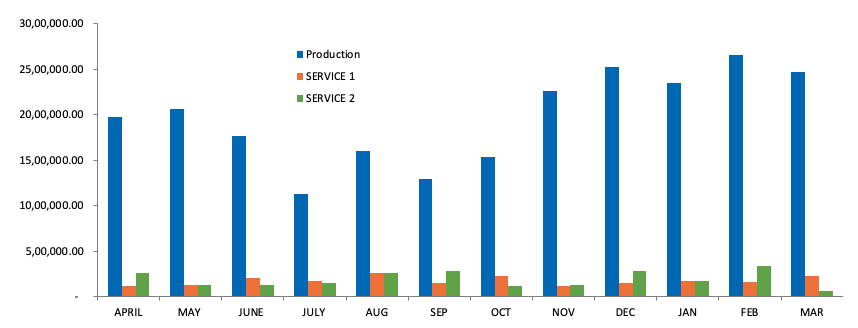

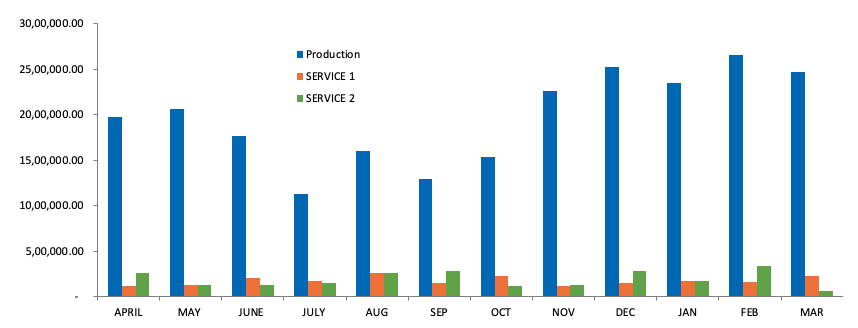

This Graph is result of the our engagement with the client from Aug 23

Boosted Employee Engagement:

Fostered a motivated and dynamic workforce through strategic initiatives.Cultivated Ownership:

Empowered employees to take responsibility and pride in their roles.Daily Morning Meetings:

Established consistent, short meetings to kick-start the day with focus and alignment.Structured Weekly Meetings:

Held regular check-ins to track progress, address challenges, and maintain momentum.Comprehensive Monthly Scorecard Reviews:

Evaluated performance metrics to ensure continuous improvement and transparency.Accountability and Responsibility Awareness:

Promoted a culture of accountability, leading to increased productivity and commitment

Month wise Production Report 2023 - 24

| Particulars |

APRIL |

MAY |

JUNE |

JULY |

AUG |

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

TOTAL |

| Production |

19,69,943.50 |

20,63,323.00 |

17,68,666.00 |

11,28,325.00 |

15,98,958.00 |

12,87,164.00 |

15,30,676.00 |

22,59,305.00 |

25,23,491.77 |

23,47,090.00 |

26,54,275.00 |

24,67,161.00 |

2,35,98,378.27 |

| SERVICE 1 |

1,20,850.00 |

1,24,540.00 |

2,03,940.00 |

1,68,929.00 |

2,62,074.00 |

1,47,655.00 |

2,29,859.00 |

1,13,347.00 |

1,46,585.00 |

1,68,350.00 |

1,60,510.00 |

2,23,230.00 |

20,69,869.00 |

| SERVICE 2 |

2,57,031.00 |

1,27,884.00 |

1,26,255.00 |

1,48,064.00 |

2,53,641.00 |

2,77,930.00 |

1,19,840.00 |

1,22,730.00 |

2,78,030.00 |

1,67,385.00 |

3,40,985.00 |

65,220.00 |

22,84,995.00 |

| TOTAL |

23,47,824.50 |

23,15,747.00 |

20,98,861.00 |

14,45,318.00 |

21,14,673.00 |

17,12,749.00 |

18,80,375.00 |

24,95,382.00 |

29,48,106.77 |

26,82,825.00 |

31,55,770.00 |

27,55,611.00 |

2,79,53,242.27 |

Gems Presentation Worksheet ->

Training Feedback

1. Visibility and Ownership

- Increased visibility of tasks and ownership.

- Greater awareness of individual responsibilities.

2. Accountability and Quality:

- Enhanced accountability among team members.

- Reduction in final rejection rates from 6% to 2%.

3. Responsibility and Communication:

- Workers are taking more responsibility in their roles.

- Improved interaction and communication between team members.

- Narrowed communication gaps during Service Level Agreement discussions.

4. Team Dynamics:

- Improved teamwork and collaboration.

- Initiation of idea generation within teams.

5. Operational Efficiency:

- Machine uptime has improved due to morning meetings.

- Increased adherence to ABSA system and processes.

- Reduced setup times and focused efforts on cycle time reduction.

- A systematic approach towards SOP-driven work.

6. Skill Development and Continuous Improvement:

- Adoption of a learning mindset among workers due to multi skilling chart visibility.

- Implementation of one-page lessons to facilitate continuous improvement.

Production Capacity and Productivity Improvement

1. Understanding Bottleneck:

- Identified critical bottlenecks in the production process.

2. Skill Set Analysis and Introduction of Robo Cell:

- Introduced the first robo cell in control panels manufacturing.

- Reduced dependency on skilled manpower.

3. Time Study and Production Increase:

- Conducted a detailed time study.

- Increased assembly production from 100 units per day to 300 units per day.

- Improved output per man.(almost doubled)

4. Client Satisfaction and Future Plans:

- Client's customer was extremely happy with the improvements.

- Two new product lines are currently under discussion.