GeMS

Global Engineering and Management Services

having total 35+ years of individual experience in diversified Industrial & Manufacturing.

GeMS

Global Engineering and Management Services

having total 35+ years of individual experience in diversified Industrial & Manufacturing.

Industry 4.0 Transformation

We have over 35 years of experience in diverse Industrial and Manufacturing fields, and have actively contributed to the transformation from traditional industries to Industry 4.0.

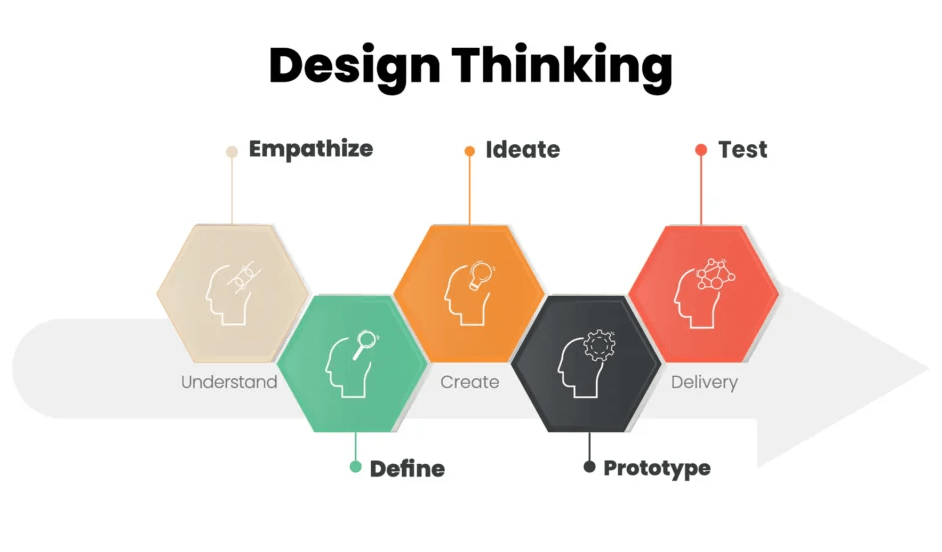

Customised Solutions

We provide customised solutions to strengthen areas of improvement for our clients. This is achieved through a systematic approach that includes data collection, analysis, root cause identification, solution derivation, and implementation.

Associated Partners Network

We have a network of associated partners across various domains. This allows us to leverage their manufacturing facilities for the benefit of our clients, making the process simpler, more cost-effective, and time-bound.

Welcome toGeMSGlobal Engineering and Management Services

We are a dynamic team of techno-commercial professionals, each bringing a wealth of over 35 years of individual experience in diverse Industrial and Manufacturing fields. Our hands-on experience has been instrumental in the transformation of traditional industries into Industry 4.0. We pride ourselves on our ability to develop and change the mindset of working teams by focusing on their strengths. Our mission is to support our clients by providing customised solutions that strengthen areas of improvement. This is achieved through a systematic approach that includes data collection, analysis, root cause identification, solution derivation, and implementation. Our handholding process ensures that these improvements become ingrained in the system and culture of the organisations we serve. We have a network of associated partners across various domains to leverage their manufacturing facilities for the benefit of our clients.

Why ChooseGeMS

Know MoreManufacturing Engineering

We specialize in process finalization, plant/cell layout, equipment selection/ordering, cutting tool/fixturing, gauges conceptualization, and proving and handover. Our expertise ensures efficient and effective manufacturing processes.

Operational Excellence

We focus on cost optimization, process optimization, lean manufacturing, and general management support. Our approach to operational excellence helps businesses improve their bottom line and operational efficiency.

Industrial Engineering

Our capabilities include plant layout, cell layout, man/machine balancing, material handling, and productivity improvements. We apply engineering and analytical methods to improve complex processes and systems.

GeMS Services

We support our clients to provide customised solutions to strengthen the improvement areas. This is achieved by systematic study of data collection, analysis, root cause identification, deriving the solution and implementing the same. The handholding will be such that it becomes the system or the culture of the organisation to whom we serve as a client.

- Industrial Engineering

- Manufacturing Engineering

- New Project, Expansion Project Management

- Automation

- VA-VE Projects

- Material Handling

- TPM

- Asset management

- Inventory Management

- Human Resource Development

- Energy Management